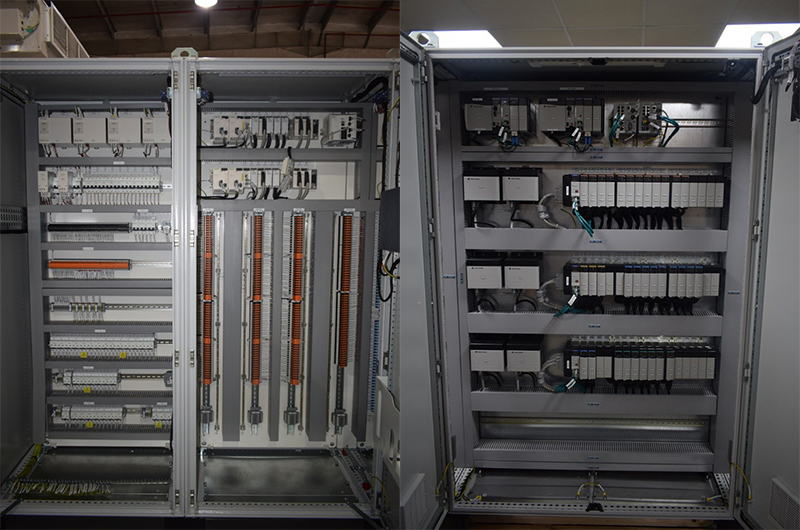

PLC control system helps to realize the process and plant performance in the safe, reliable and efficient manner. With over 25 years’ of experience, we can provide the strategic automation solution that enable your process to operate safe and efficiently as possible. Our extensive experience together with highly skilled resources helps to deliver the control system in best workmanship and good industrial practice. Automation is not limited to programming and graphic development, it features an integrated control system design includes defining networks, third party system integration and collaborated with process engineers to define the control philosophy and shut down / cause & effect matrix procedure.

We partnered with leading manufacturer in PLC, HMI, SCADA and provide the integrated control system which includes the following services:

- Control system conceptual design.

- Control system network design and development.

- Defining the control philosophy, cause & Effect matrix in collaboration with process designers.

- Commissioning and start-up service.

- Annual maintenance contract / on-call service support.

We have successfully executed PLC based industrial Automation and control system for following applications integrated with HMI, SCADA

- Standalone, high available control system for process automation

- SIL rated safety system

- Fault Tolerance control system for time critical application

- Control system for harsh environment installation

- Custom built solutions for Original Equipment Manufacturer (OEM)

- Machine and factory automation with integrated motion control & safety technology

Our factory equipped with simulation / demo kit which enable our client to have functional factory testing rather than just hardware inspection. We have also facilitated the “heat soak test” chamber to carry the heat soak test as called by project specification.